HANDLING THE ARC FLASH HAZARD

HANDLING THE ARC FLASH HAZARD

THE UNKNOWN ELECTRICAL HAZARD

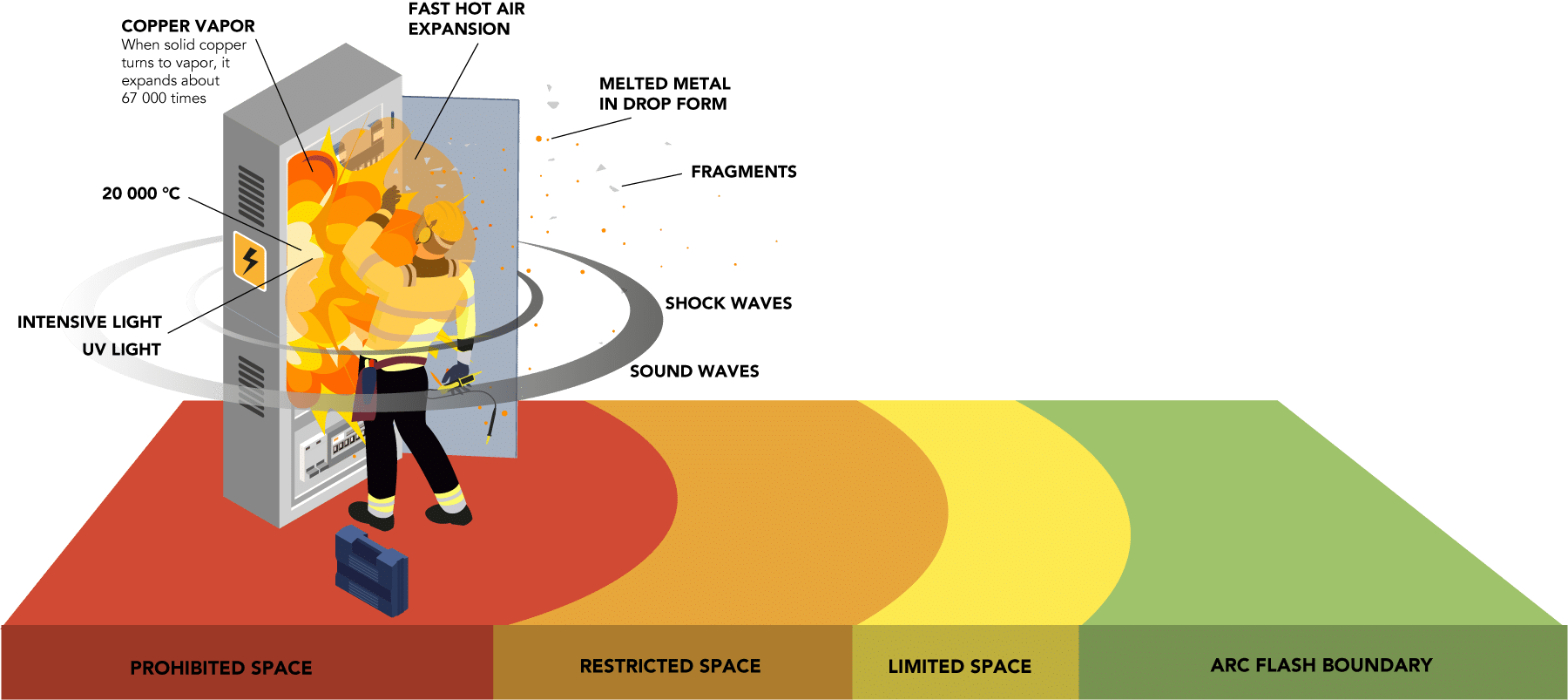

Burns, cracked eardrums, burnt corneas, inhalation of toxic gases and flying metal parts. For those who happen to be standing nearby, an arc accident is like an explosion.

Arc flashes constitutes almost a third (31.8%) of all electrical accidents that resulted in sick leave of electricians during the 2000s. Despite this, the danger of arc flashes is surprisingly unknown, even in the energy industry. Many companies lack proper safety measures.

What is an arc flash?

It looks like a bolt of lightning strikes the electrical equipment. When the voltage in the equipment ionizes the air so that it becomes electrically conductive, strong electrical discharge can occur.

Most often, a short circuit is the triggering factor. The cause may be a technical error, but in most cases a human error is behind it.

Enormous amounts of energy are released in the form of heat, light, sound and shock waves. For example, solid copper can expand 67,000 times when the metal in an explosion is converted from solid to gas. The temperature can reach 10-20 thousand degrees.

THE UNKNOWN ELECTRICAL HAZARD

Burns, cracked eardrums, burnt corneas, inhalation of toxic gases and flying metal parts. For those who happen to be standing nearby, an arc accident is like an explosion.

Arc flashes constitutes almost a third (31.8%) of all electrical accidents that resulted in sick leave of electricians during the 2000s. Despite this, the danger of arc flashes is surprisingly unknown, even in the energy industry. Many companies lack proper safety measures.

What is an arc flash?

It looks like a bolt of lightning strikes the electrical equipment. When the voltage in the equipment ionizes the air so that it becomes electrically conductive, strong electrical discharge can occur.

Most often, a short circuit is the triggering factor. The cause may be a technical error, but in most cases a human error is behind it.

Enormous amounts of energy are released in the form of heat, light, sound and shock waves. For example, solid copper can expand 67,000 times when the metal in an explosion is converted from solid to gas. The temperature can reach 10-20 thousand degrees.

Why you need to deal with the danger of arc flashes

Of course, staff must be able to work in the facility without risking their life. At the same time, there is a risk for the company that an arc flash accident will result in prosecution, damaged reputation and claims for damages. Even a minor arc event can lead to damage to the electricity grid, downtime, loss of production and costs for decontamination, replacement and so on.

The legislation affects both plant owners and employers. The owner is responsible for ensuring that it is safe to be at or in the vicinity of the facility, the employer is obliged to ensure that employees are aware of the risks and have the right protective equipment.

Why you need to deal with the danger of arc flashes

Of course, staff must be able to work in the facility without risking their life. At the same time, there is a risk for the company that an arc flash accident will result in prosecution, damaged reputation and claims for damages. Even a minor arc event can lead to damage to the electricity grid, downtime, loss of production and costs for decontamination, replacement and so on.

The legislation affects both plant owners and employers. The owner is responsible for ensuring that it is safe to be at or in the vicinity of the facility, the employer is obliged to ensure that employees are aware of the risks and have the right protective equipment.

WHAT DOES THE LAW SAY?

The legislation in this area affects both the plant owner and the employer

The proprietor’s responsibility

The system must be designed so that it does not pose a risk of personal injury or property damage due to high temperatures, arc flashes or mechanical stresses caused by current during normal operation or by overcurrent. There must always be at least two barriers present in a facility. The barriers must provide reassuring safety under normal conditions, in the event of a fault or in the event of reasonably foreseeable incorrect service.

The owner of a facility must assess the risks at the facility and ensure that warning labels are available where necessary to warn or inform about risks that exist due to electricity.

The employer’s responsibility

The employer must take all necessary measures to prevent the employee from being exposed to ill health or accidents. Reassuring protective measures must be taken against damage by electric current.

When working at or in the vicinity of a live installation, safety measures must be taken to prevent those who participate in the work from being injured by current, the effect of an arc flash or a short circuit.

When the risks at work are serious, there must be written instructions.

Those who work where there is an electrical hazard must have knowledge of the meaning and consequences of the hazard and be trained in the safety measures that are necessary in relation to the tasks. This means not only having appropriate technical knowledge but also an understanding of the dangers, risks and regulations that must be followed.

The employer must provide the personal protective equipment required for the job. Before choosing protective equipment, the employer must assess the risks at work and what properties the equipment must protect against.

WHAT DOES THE LAW SAY?

The legislation in this area affects both the plant owner and the employer

The proprietor’s responsibility

The system must be designed so that it does not pose a risk of personal injury or property damage due to high temperatures, arc flashes or mechanical stresses caused by current during normal operation or by overcurrent. There must always be at least two barriers present in a facility. The barriers must provide reassuring safety under normal conditions, in the event of a fault or in the event of reasonably foreseeable incorrect service.

The owner of a facility must assess the risks at the facility and ensure that warning labels are available where necessary to warn or inform about risks that exist due to electricity.

The employer’s responsibility

The employer must take all necessary measures to prevent the employee from being exposed to ill health or accidents. Reassuring protective measures must be taken against damage by electric current.

When working at or in the vicinity of a live installation, safety measures must be taken to prevent those who participate in the work from being injured by current, the effect of an arc flash or a short circuit.

When the risks at work are serious, there must be written instructions.

Those who work where there is an electrical hazard must have knowledge of the meaning and consequences of the hazard and be trained in the safety measures that are necessary in relation to the tasks. This means not only having appropriate technical knowledge but also an understanding of the dangers, risks and regulations that must be followed.

The employer must provide the personal protective equipment required for the job. Before choosing protective equipment, the employer must assess the risks at work and what properties the equipment must protect against.

OUR APPROACH

Our method is proven. It has been refined gradually with the support of experience from previous assignments.

What are the right measures needs to be assessed on a case-by-case basis. With calculations as a basis, we propose measures and ensure that these are implemented.

We ensure that:

- employees understand the danger of arc flashes and can handle it in their everyday life

- no risk is deemed to have been managed until the measure takes effect.

.

OUR APPROACH

Our method is proven. It has been refined gradually with the support of experience from previous assignments.

What are the right measures needs to be assessed on a case-by-case basis. With calculations as a basis, we propose measures and ensure that these are implemented.

We ensure that:

- employees understand the danger of arc flashes and can handle it in their everyday life

- no risk is deemed to have been managed until the measure takes effect.

SAFE ENERGY

OUR OFFER

FOCUS AREAS

SAFE ENERGY

OUR OFFER

FOCUS AREAS

CONTACT US

© 2024 Peritum AB

CONTACT US

© 2024 Peritum AB